Analysis of corrugated paper boxes: the main packaging force from structure to application

In modern packaging, corrugated boxes are packaging containers made with corrugated cardboard as their core material. Due to their unique structural advantages and wide applicability, they have become one of the most widely used packaging formats worldwide. They not only fulfill the fundamental functions of protecting goods and facilitating transportation, but also, with technological advancements, their applications are continuously expanding, becoming a crucial link between production, distribution, and consumption.

Structurally, the core of corrugated boxes lies in the "fluting"—the corrugated middle layer of cardboard. This structure consists of at least one layer of corrugated core paper (corrugated) bonded to one or more layers of flat containerboard, forming a "sandwich" composite structure. Fluting is commonly found in U-shaped, V-shaped, or UV-type combinations. U-shaped corrugation is widely used for its excellent cushioning and resilience. Based on the height and density of the flutes, corrugated cardboard can be categorized into various types, including A, B, C, E, and F. For example, A flutes are taller (approximately 4.5-5mm) and offer superior cushioning properties, making them suitable for packaging fragile items. E flutes are only 1.1-2mm tall and offer excellent flatness, making them commonly used as gift box linings or for packaging small electronic products.

Corrugated cardboard primarily uses pulp from sources such as wood fiber and recycled waste paper. In recent years, with the growing awareness of environmental protection, the use of recycled pulp has continued to increase. For example, companies like Urumqi Bingxin Environmental Protection Packaging Co., Ltd. produce corrugated cardboard from recycled waste paper, reducing wood consumption and promoting resource recycling. Data shows that high-quality corrugated cardboard can achieve a waste paper utilization rate of over 80%, and the finished product is 100% recyclable, making corrugated cardboard a leading environmentally friendly packaging material.

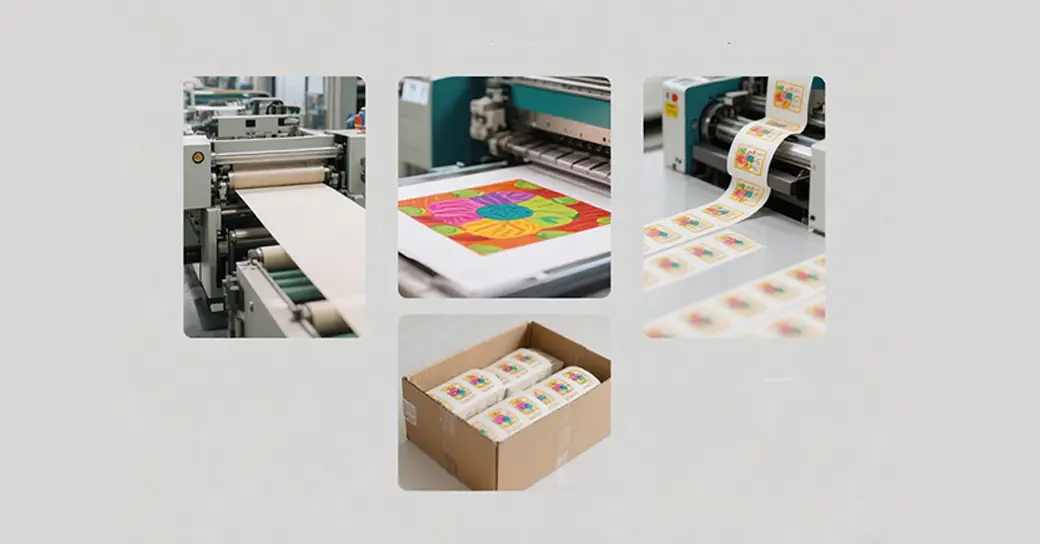

The development of corrugated cardboard dates back to the late 19th century, initially used for simple packaging. In the mid-20th century, with the introduction of mechanized production technology, production efficiency and structural stability increased significantly, gradually replacing wooden boxes as the mainstay of transport packaging. Entering the 21st century, intelligence and personalization became key development keywords in the industry. For example, Nantong Aijia Packaging Technology Co., Ltd. uses 5G and robotic arm technology to achieve fully automated production, producing 250-280 customized paper boxes per minute, meeting the small-batch, multi-format packaging needs of the e-commerce era.

Today, the use of corrugated paperboard has permeated nearly all industries. In logistics, it is the "standard" for express parcels. Hunan Post alone recycles and reuses nearly 4.7 million corrugated boxes annually. In the food industry, corrugated paperboard with waterproof and moisture-proof treatments can be used for packaging fresh and frozen foods. In consumer electronics, E-flute corrugated paperboard, with its delicate surface texture, has become the gift box of choice for high-end digital products. Even in the creative field, the plasticity of corrugated paper is being fully explored. Zhou Mo, an 8-year-old boy from Wuhan, created an interactive 3D model using corrugated paper, demonstrating the creative value of this material beyond packaging. With the global emphasis on sustainable development and the advancement of intelligent supply chains, corrugated paperboard is experiencing new development opportunities. From embedding RFID tags for full traceability to using plant-based inks for enhanced environmental performance, corrugated paperboard continues to upgrade towards efficiency, intelligence, and greenness while maintaining cost advantages, solidifying its core position in the packaging industry.